Constructing inviting 3D nanomaterials with DNA

Columbia Engineering researchers, working with Brookhaven National Laboratory, report as of late that they’ve built designed nanoparticle-based 3D materials that can withstand a vacuum, high temperatures, high stress, and high radiation. This sleek fabrication direction of finally ends up in grand and absolutely engineered nanoscale frameworks that not easiest can accommodate a fluctuate of purposeful nanoparticle kinds but additionally could maybe even be hasty processed with in vogue nanofabrication methods.

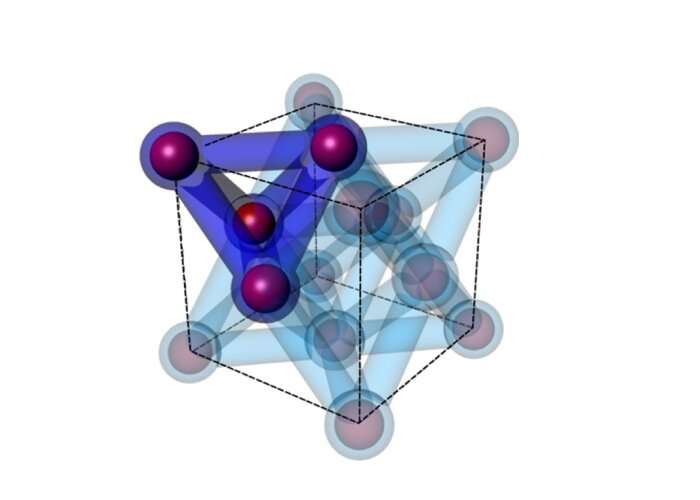

“These self-assembled nanoparticles-based materials are so resilient that they’d wing in space,” says Oleg Gang, professor of chemical engineering and of applied physics and materials science, who led the gape revealed as of late by Science Advances. “We were ready to transition 3D DNA-nanoparticle architectures from liquid issue—and from being a pliable discipline matter—to solid issue, where silica re-enforces DNA struts. This sleek discipline matter absolutely maintains its fashioned framework structure of DNA-nanoparticle lattice, actually making a 3D inorganic replica. This allowed us to uncover—for the distinguished time—how these nanomaterials can battle harsh conditions, how they devise, and what their properties are.”

Self-discipline matter properties are diversified on the nanoscale and researchers receive long been exploring pointers on how to use these runt materials—1,000 to 10,000 times smaller than the thickness of a human hair—in all forms of applications, from making sensors for telephones to building faster chips for laptops. Fabrication tactics, nevertheless, were inviting in realizing 3D nano-architectures. DNA nanotechnology permits the appearance of complexly organized materials from nanoparticles by self-assembly, but given the soft and surroundings-dependent nature of DNA, such materials could maybe well very well be exact below easiest a slim fluctuate of conditions. In distinction, the newly formed materials can now be aged in a gargantuan fluctuate of applications where these engineered constructions are required. While in vogue nanofabrication excels in creating planar constructions, Gang’s sleek way permits for fabrication of 3D nanomaterials that are becoming important to so many digital, optical, and energy applications.

Gang, who holds a joint appointment as neighborhood leader of the Delicate and Bio Nanomaterials Neighborhood at Brookhaven Lab’s Heart for Purposeful Nanomaterials, is on the forefront of DNA nanotechnology, which relies on folding DNA chain into desired two and three-dimensional nanostructures. These nanostructures turn into building blocks that will maybe even be programmed by Watson-Crick interactions to self-assemble into 3D architectures. His neighborhood designs and kinds these DNA nanostructures, integrates them with nanoparticles and directs the assembly of focused nanoparticle-based materials. And, now, with this sleek technique, the team of workers can transition these materials from being soft and fragile to solid and grand.

This sleek gape demonstrates an surroundings pleasant way for changing 3D DNA-nanoparticle lattices into silica replicas, while declaring the topology of the interparticle connections by DNA struts and the integrity of the nanoparticle group. Silica works well because it helps do away with the nanostructure of the parent DNA lattice, kinds a grand solid of the underlying DNA and doesn’t affect nanoparticles arrangements.

“The DNA in such lattices takes on the properties of silica,” says Aaron Michelson, a Ph.D. pupil from Gang’s neighborhood. “It becomes exact in air and could even be dried and permits for 3D nanoscale prognosis of the discipline matter for the distinguished time in right space. Moreover, silica offers power and chemical balance, it be low-cost and could even be modified as needed—it be a actually helpful discipline matter.”

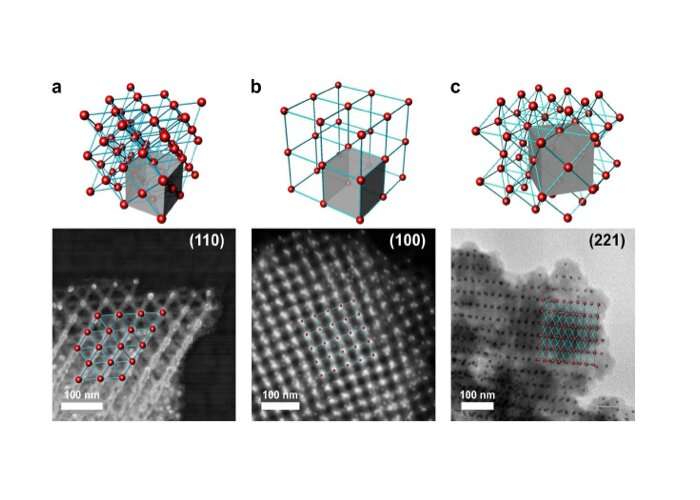

To learn more relating to the properties of their nanostructures, the team of workers exposed the transformed to silica DNA-nanoparticles lattices to uncouth conditions: high temperatures above 1,0000C and high mechanical stresses over 8GPa (about 80,000 times greater than atmosphere stress, or 80 times greater than on the deepest ocean role, the Mariana trench), and studied these processes in-situ. To gauge the constructions’ viability for applications and further processing steps, the researchers additionally exposed them to high doses of radiation and focused ion beams.

“Our prognosis of the applicability of those constructions to couple with in vogue nanofabrication tactics demonstrates a actually grand platform for generating resilient nanomaterials by DNA-based approaches for discovering their sleek properties,” Gang notes. “It’s a ways a extensive step ahead, as these explicit properties point out that we can use our 3D nanomaterial assembly and soundless earn admission to the fat fluctuate of in vogue materials processing steps. This integration of sleek and in vogue nanofabrication methods is needed to make advances in mechanics, electronics, plasmonics, photonics, superconductivity, and energy materials.”

Collaborations based on Gang’s work receive already led to sleek superconductivity and conversion of the silica to conductive and semiconductive media for further processing. These consist of an earlier gape revealed by Nature Communications and one not too long ago revealed by Nano Letters. The researchers are additionally planning to adjust the advance to create a gargantuan fluctuate of materials with highly well-organized mechanical and optical properties.

“Computers were made with silicon for over 40 years,” Gang provides. “It took four an extended time to push the fabrication all the diagram down to about 10 nm for planar constructions and devices. Now we can create and assemble nanoobjects in a test tube in a pair of hours with out costly tools. Eight billion connections on a single lattice can now be orchestrated to self-assemble by nanoscale processes that we can engineer. Each and every connection could maybe well very well be a transistor, a sensor, or an optical emitter—each could maybe even be barely data stored. While Moore’s law is slowing, the programmability of DNA assembly approaches is there to beget us ahead for solving concerns in sleek materials and nanomanufacturing. While this has been extraordinarily inviting for most up-to-date methods, it is tremendously important for emerging technologies.”

Extra data:

“Resilient three-dimensional ordered architectures assembled from nanoparticles by DNA” Science Advances (2021). advances.sciencemag.org/look up … .1126/sciadv.abf0617

Citation:

Constructing inviting 3D nanomaterials with DNA (2021, March 19)

retrieved 19 March 2021

from https://phys.org/news/2021-03-inviting-3d-nanomaterials-dna.html

This doc is discipline to copyright. Rather then any very most absorbing dealing for the cause of non-public gape or study, no

share could maybe well very well be reproduced with out the written permission. The sigh material is supplied for data functions easiest.