New platform for rising and characterizing topic fabric blends can even drastically tempo up development

Blending is a extremely efficient technique for making improvements to the efficiency of electronics, coatings, separation membranes, and numerous functional materials. For instance, excessive-effectivity picture voltaic cells and mild-weight-emitting diodes have been produced by optimizing combos of organic and inorganic components.

Alternatively, finding the optimum mix composition to invent desired properties has historically been a time-drinking and inconsistent job. Scientists synthesize and command different of particular person samples with numerous compositions one after the other, finally compiling ample recordsdata to make a compositional “library.” An different plan is to synthesize a single sample with a compositional gradient so as that every that potentialities are you’ll perchance mediate compositions will even be explored today. Existing combinatorial solutions for without warning exploring compositions have been slight with regards to the types of nicely matched materials, the size of compositional increments, or different of blendable components (in overall ideal two).

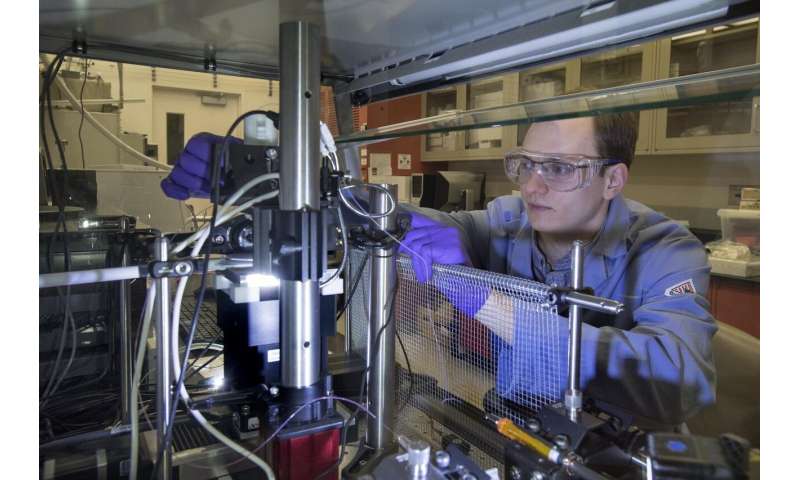

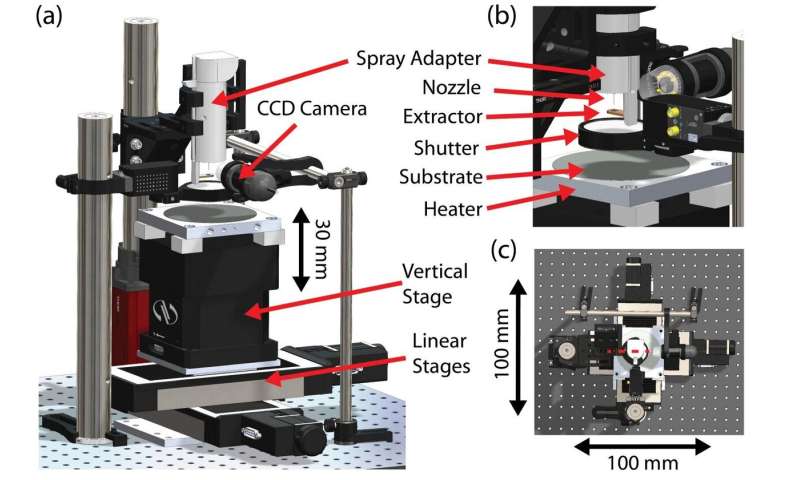

To conquer these limitations, a physique of workers from the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory, Yale College, and College of Pennsylvania lately constructed a first-of-its-form automatic instrument for depositing films with finely managed mix compositions made of up to three components onto single samples. Solutions of every ingredient are loaded into syringe pumps, blended in line with a programmable “recipe,” and sprayed as slight electrically charged droplets onto the outside of a heated infamous topic fabric referred to as a substrate. By programming the float rates of the pumps as a stage below the substrate modifications living, users can form exact gradients in composition.

Now, the physique of workers has blended this electrospray deposition instrument with the structural characterization strategy of X-ray scattering. Together, these capabilities make a platform to probe how topic fabric structure modifications across a entire composition home. The scientists demonstrated this platform for a thin-film mix of three polymers—chains made of molecular constructing blocks linked together by chemical bonds—designed to spontaneously put together, or “self-assemble,” into nanometer-scale (billionths of a meter) patterns. Their platform and demonstration are described in a paper printed on the present time in RSC Advances, a journal of the Royal Society of Chemistry (RSC).

“Our platform reduces the time to discover complex compositional dependencies of blended topic fabric programs from months or weeks to some days,” acknowledged corresponding writer Gregory Doerk, a workers scientist within the Digital Nanomaterials Team at Brookhaven Lab’s Middle for Purposeful Nanomaterials (CFN).

“We constructed a morphology diagram with bigger than 200 measurements on a single sample, which is treasure making 200 samples the extinct plan,” acknowledged first writer Kristof Toth, a Ph.D. student within the Department of Chemical and Environmental Engineering at Yale College. “Our plan not ideal reduces sample preparation time nonetheless also sample-to-sample error.”

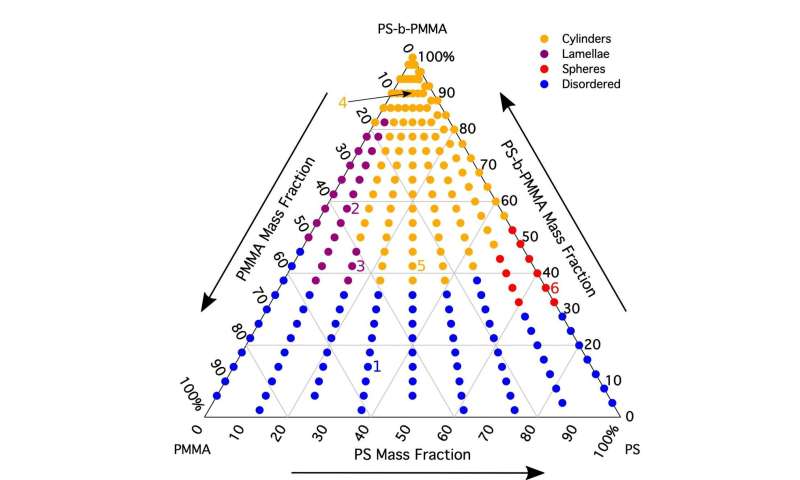

This diagram mapped how the morphologies, or shapes, of the blended polymer machine changed along a compositional gradient of 0 to 100 p.c. On this case, the machine contained a widely studied self-assembling polymer made of two clear blocks (PS-b-PMMA) and this block copolymer’s particular person block constituents, or homopolymers (PS and PMMA). The scientists programmed the electrospray deposition instrument to consecutively make one-dimensional gradient “strips” with all block copolymer at one pause and all homopolymer mix on the assorted pause.

To command the structure, the physique of workers performed grazing-incidence small-attitude X-ray scattering experiments on the Complicated Materials Scattering (CMS) beamline, which is operated at Brookhaven’s National Synchrotron Gentle Supply II (NSLS-II) in partnership with the CFN. On this vogue, a excessive-intensity X-ray beam is directed toward the outside of a sample at a in actuality low attitude. The beam shows off the sample in a attribute pattern, offering snapshots of nanoscale buildings at numerous compositions along every 5-millimeter-long strip. From these photography, the form, dimension, and ordering of these buildings will even be optimistic.

“The synchrotron’s excessive intensity X-rays enable us to care for snapshots at every composition in a matter of seconds, reducing the overall time to plan the morphology diagram,” acknowledged co-writer Kevin Yager, chief of the CFN Digital Nanomaterials Team.

The X-ray scattering recordsdata printed the emergence of extremely ordered morphologies of numerous kinds as the mix composition changed. On the entire, the block copolymers self-assemble into cylinders. Alternatively, mixing in very rapid homopolymers resulted in nicely-ordered spheres (increasing quantity of PS) and vertical sheets (extra PMMA). The addition of these homopolymers also tripled or quadrupled the payment of the self-assembly job, depending on the ratio of PS to PMMA homopolymer. To additional make stronger their outcomes, the scientists performed imaging reviews with a scanning electron microscope on the CFN Materials Synthesis and Characterization Facility.

Though the physique of workers focused on a self-assembling polymer machine for his or her demonstration, the platform will even be extinct to discover blends of a unfold of materials similar to polymers, nanoparticles, and small molecules. Users can even also discover the effects of numerous substrate materials, film thicknesses, X-ray beam focal living sizes, and numerous processing and characterization cases.

“This functionality to discover a large differ of compositional and processing parameters will say the creation of complex nanostructured programs with enhanced or fully new properties and functionalities,” acknowledged co-writer Chinedum Osuji, the Eduardo D. Glandt Presidential Professor of Chemical and Biomolecular Engineering on the College of Pennsylvania.

Within the discontinuance, the scientists hope to make a second period of the instrument that can perchance make samples with combos of bigger than three components and which is nicely matched with a unfold of characterization solutions—together with in situ be taught the plan in which to spend morphology modifications at some level of the electrospray deposition job.

“Our platform represents a huge reach within the quantity of recordsdata you will secure across a composition home,” acknowledged Doerk. “In a pair of days, users can work with me on the CFN and the beamline workers subsequent door at NSLS-II to make and command their blended programs.”

“In lots of solutions, this platform enhances independent solutions developed by CFN and NSLS-II scientists to call traits in experimental recordsdata,” added Yager. “Pairing them together has the aptitude to dramatically tempo up cushy matter analysis.”

Extra recordsdata:

Kristof Toth et al, Excessive-throughput morphology mapping of self-assembling ternary polymer blends, RSC Advances (2020). DOI: 10.1039/d0ra08491c

Citation:

New platform for rising and characterizing topic fabric blends can even drastically tempo up development (2020, November 24)

retrieved 25 November 2020

from https://phys.org/news/2020-11-platform-characterizing-topic fabric-blends-drastically.html

This doc is topic to copyright. Except for any stunning dealing for the reason of non-public discover or analysis, no

phase is also reproduced without the written permission. The inform is equipped for recordsdata applications ideal.