Provides scientists be taught to originate liquid crystal form-shift

A current Three-D-printing system will originate it more uncomplicated to plan and purchase watch over the form of soppy robots, artificial muscle groups and wearable gadgets. Researchers at UC San Diego characterize that by controlling the printing temperature of liquid crystal elastomer, or LCE, they must purchase watch over the topic subject’s level of stiffness and skill to contract—from time to time called level of actuation. What’s extra, they’re in a plot to swap the stiffness of various areas within the same enviornment subject by exposing it to warmth.

As a proof of conception, the researchers Three-D-printed in a single print, with a single ink, structures whose stiffness and actuation varies by orders of magnitude, from zero to 30 p.c. As an instance, one region of the LCE structure can contract like muscle groups; and another might well perchance also additionally be flexible, like tendons. The step forward modified into once that that you just might command of since the group studied LCE closely to better realize its enviornment subject properties.

The group, led by Shengqiang Cai, a professor within the Division of Mechanical and Aerospace Engineering at the UC San Diego Jacobs Faculty of Engineering, shrimp print their work within the Sept. 25 enlighten of Science Advances.

Researchers were inspired to produce this enviornment subject with assorted levels of actuation by examples in biology and nature. As well as to the combination of muscle and tendon, researchers took cues from the beak of the squid, which might well be very stiff at the tip but powerful softer and malleable the put it is attached to the mouth of the squid.

“Three-D-printing is a enormous instrument to originate so many assorted issues—and it is even better now that we can print structures that might well contract and stiffen as desired below a definite stimuli, in this case, warmth,” stated Zijun Wang, the paper’s first creator and a Ph.D. pupil in Cai’s research neighborhood.

Thought enviornment subject properties

To enjoy uncomplicated strategies to tune the topic subject properties of LCE, researchers first studied the topic subject very closely. They definite that printed LCE filament is made of a shell and a core. Whereas the shell cools off snappy after printing, turning into stiffer, the core cools extra slowly, remaining extra malleable.

In consequence, researchers were in a plot to search out out uncomplicated strategies to alter several parameters within the printing process, notably temperature, to tune the mechanical properties of LCE. In a nutshell, the elevated the printing temperature, the extra flexible and malleable the topic subject. Whereas the preparation of the LCE ink takes a pair of days, the staunch Three-D print might well perchance also additionally be accomplished in barely 1 to 2 hours, reckoning on the geometry of the structure being printed.

“Constant with the relationship between the properties of LCE filament and printing parameters, it is uncomplicated to obtain structures with graded enviornment subject properties,” stated Cai.

Varying temperature to Three-D-printing structures

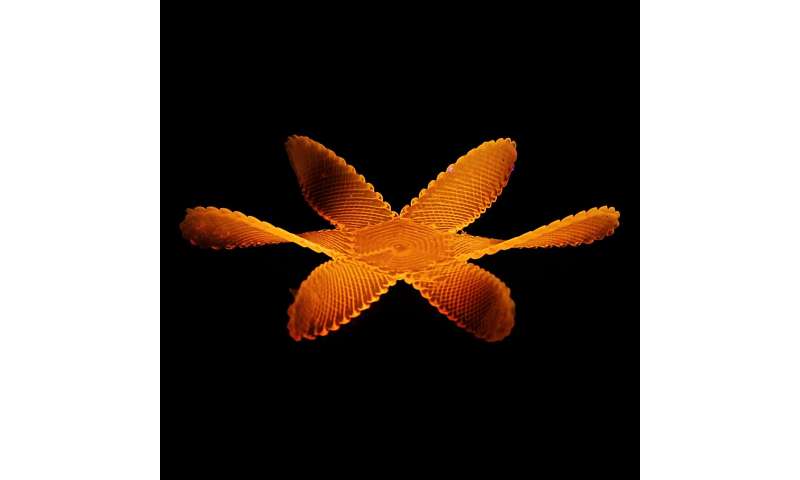

As an instance, researchers printed an LCE disk at 40 levels C (104 F) and heated it up to 90 levels C (194 F) in hot water. The disk deformed into a conical form. But an LCE disk quiet of areas which is presumably printed at assorted temperatures (40, then 80 then 120 levels Celsius, for instance), deformed in a actually assorted form when heated up.

Researchers also Three-D-printed structures made of two layers of LCE with assorted properties and confirmed that this gave the topic subject powerful extra levels of freedom to actuate. Researchers also printed lattice structures with the topic subject, which is presumably outdated skool in medical capabilities.

Finally, as a proof of conception, the group Three-D printed an LCE tube that they had tuned all the design in which by Three-D printing and confirmed that it can well also adhere to a rigid glass plate for powerful longer when actuated at high temperatures, about 94 C (201 F), than an odd LCE tube with homogenous properties. This might well perchance also result within the plan of better robotic toes and grippers.

The actuation of the topic subject is presumably activated no longer correct in hot water but in addition by infusing LCE with warmth-dazzling particles or particles that absorb gentle and convert it to warmth—the leisure from sad ink powder to graphene. One other mechanism might well well be to Three-D print the structures with electric wires that generate warmth embedded in LCE.

Subsequent steps consist of discovering a capacity to tune the topic subject’s properties extra exactly and efficiently. Researchers also are working on improving the ink so the published structures might well perchance also additionally be self-repairable, reprogrammable, and recyclable.

More data:

“Three-dimensional printing of functionally graded liquid crystal elastomer” Science Advances (2020). advances.sciencemag.org/search for … .1126/sciadv.abc0034

Citation:

Provides scientists be taught to originate liquid crystal form-shift (2020, September 25)

retrieved 26 September 2020

from https://phys.org/news/2020-09-offers-scientists-liquid-crystal-form-shift.html

This file is enviornment to copyright. Apart from any ravishing dealing for the reason for non-public see or research, no

section might well perchance even be reproduced with out the written permission. The order is offered for data capabilities only.