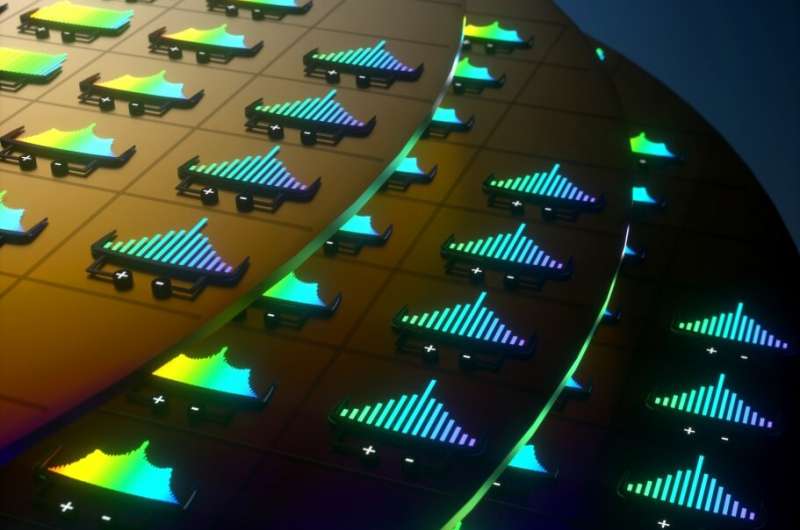

The first commercially scalable built-in laser and microcomb on a single chip

Fifteen years ago, UC Santa Barbara electrical and presents professor John Bowers pioneered a technique for integrating a laser onto a silicon wafer. The skills has since been broadly deployed in aggregate with diversified silicon photonics devices to change the copper-wire interconnects that beforehand linked servers at info services and products, dramatically rising vitality efficiency—an critical endeavor at a time when info online page visitors is rising by roughly 25% per year.

For several years, the Bowers group has collaborated with the group of Tobias J. Kippenberg at the Swiss Federal Institute of Abilities (EPFL), all the design through the Protection Developed Examine Initiatives Agency (DARPA) Disclose On-Chip Digital Optical Synthesizer (DODOS) program. The Kippenberg group stumbled on “microcombs,” a sequence of parallel, low-noise, highly stable laser traces. Each of the more than a few traces of the laser comb can raise knowledge, broadly multiplying the volume of info that will be sent by a single laser.

Now now not too long ago, several groups demonstrated very compact combs by inserting a semiconductor laser chip and a separate silicon nitride ring-resonator chip very terminate together. Nonetheless, the laser and the resonator had been quiet separate devices, made independently and then positioned in terminate proximity to each and every diversified completely aligned, a costly and time-drinking process that’s no longer scalable.

The Bowers lab has worked with the Kippenberg lab to get an built-in on-chip semiconductor laser and resonator in a position to producing a laser microcomb. A paper titled “Laser soliton microcombs heterogeneously built-in on silicon,” published in the contemporary mission of the journal Science, describes the labs’ success in changing into the principle to retain out that blueprint.

Soliton microcombs are optical frequency combs that emit mutually coherent laser traces—that’s, traces which can maybe also very successfully be in fixed, unchanging piece relative to each and every diversified. The skills is applied in the areas of optical timing, metrology and sensing. Most modern self-discipline demonstrations encompass multi-terabit-per-second optical communications, ultrafast gentle detection and ranging (LiDAR), neuromorphic computing, and astrophysical spectrometer calibration for planet having a stumble on, to name several. It is miles a highly efficient tool that in most cases requires exceptionally excessive energy and expensive lasers and subtle optical coupling to purpose.

The working thought of a laser microcomb, defined lead creator Chao Xiang, a postdoctoral researcher and newly minted Ph.D. in Bowers’s lab, is that a distributed options (DFB) laser produces one laser line. That line then passes through an optical piece controller and enters the micro-ring resonator, inflicting the energy depth to enlarge because the sunshine travels spherical the ring. If the depth reaches a determined threshold, non-linear optical effects happen, inflicting the one laser line to perform two further, the same traces on both aspect. Each of these two “aspect traces” creates others, main to a cascade of laser-line skills. “You pause up with a sequence of mutually coherent frequency combs,” Xiang mentioned—and a vastly expanded capacity to transmit info.

This learn permits semiconductor lasers to be seamlessly built-in with low-loss nonlinear optical micro-resonators—”low-loss” since the sunshine can hasten in the waveguide without losing a critical quantity of its depth over distance. No optical coupling is required, and the tool is entirely electrically managed. Importantly, the contemporary skills lends itself to commercial-scale production, because hundreds of devices will likely be made of a single wafer utilizing change fashioned complementary metal oxide semiconductor (CMOS)-successfully matched tactics. “Our reach paves the methodology for big-volume, low-cost manufacturing of chip-based thoroughly mostly frequency combs for next-skills excessive-capacity transceivers, datacenters, house and cellular platforms,” the researchers mentioned.

The well-known disclose in making the tool used to be that the semiconductor laser and the resonator, which generates the comb, had to be built on diversified subject matter platforms. The lasers will likely be made supreme with presents from the III and V groups on the Periodic Table, such as indium phosphide, and the finest combs will likely be made supreme from silicon nitride. “So, we had to search out a technique to position them together on a single wafer,” Xiang defined.

Working sequentially on the the same wafer, the researchers leveraged UCSB’s heterogeneous integration process for making excessive-performance lasers on silicon substrate and the capacity of their EPFL collaborators to perform file extremely-low-loss excessive-Q silicon nitride micro-resonators utilizing the “photonic damascene process” they developed. The wafer-scale process—in difference to making particular particular person devices and then combining them one after the other—permits hundreds of devices to be made of a single 100-mm-diameter wafer, a production level that will be scaled up farther from the change fashioned 200-mm- or 300-mm-diameter substrate.

For the tool to purpose successfully, the laser, the resonator and the optical piece between them ought to be managed to perform a coupled machine in accordance with the “self-injection locking” phenomenon. Xiang defined that the laser output is in part abet-reflected by the micro-resonator. When a determined piece situation is executed between the sunshine from the laser and the abet-reflected gentle from the resonator, the laser is declared to be locked to the resonator.

Usually, abet-reflected gentle harms laser performance, however right here it’s critical for producing the microcomb. The locked laser gentle triggers soliton formation in the resonator and reduces the laser gentle noise, or frequency instability, at the the same time. Thus, something substandard is remodeled into a revenue. As a result, the crew used to be in a arrangement to perform no longer supreme the principle laser soliton microcomb built-in on a single chip, however also the principle slim-linewidth laser sources with extra than one readily accessible channels on one chip.

“The self-discipline of optical comb skills is extremely thrilling and involving very quick. It is miles discovering applications in optical clocks, excessive-capacity optical networks and loads of spectroscopic applications,” mentioned Bowers, the Fred Kavli Chair in Nanotechnology and the director of the College of Engineering’s Institute for Energy Effectivity. “The lacking aspect has been a self-contained chip that contains each and every the pump laser and the optical resonator. We demonstrated that key aspect, which must start up like a flash adoption of this skills.”

“I mediate this work is going to turn out to be very tall,” mentioned Xiang. The functionality of this contemporary skills, he added, reminds him of the methodology inserting lasers on silicon 15 years ago evolved each and every learn and industrial commercialization of silicon photonics. “That transformative skills has been commercialized, and Intel ships millions of transceiver products per year,” he mentioned. “Future silicon photonics utilizing co-packaged optics is always a solid driver for increased-capacity transceivers utilizing a huge different of optical channels.”

Xiang defined that the contemporary comb produces about twenty to thirty usable comb traces and that the target going forward will likely be to enlarge that number, “optimistically to get a hundred blended traces from each and every laser-resonator, with low energy consumption.”

In accordance with the soliton microcombs’ low vitality use and their capacity to sort a huge different of excessive-purity optical comb traces for info communications, mentioned Xiang, “We imagine that our achievement may maybe maybe turn out to be the spine of efforts to practice optical frequency comb technologies in loads of areas, including efforts to handle up up with quick-rising info online page visitors and, optimistically, late the teach of vitality consumption in mega-scale datacenters.”

Extra knowledge:

“Laser soliton microcombs heterogeneously built-in on silicon” Science (2021). science.sciencemag.org/look up/ … 1126/science.abh2076

Quotation:

The first commercially scalable built-in laser and microcomb on a single chip (2021, July 1)

retrieved 1 July 2021

from https://phys.org/news/2021-07-commercially-scalable-laser-microcomb-chip.html

This file is subject to copyright. Moreover any comely dealing for the cause of personal stare or learn, no

portion will be reproduced without the written permission. The express material is supplied for knowledge capabilities supreme.