How is Bamboo Trip Made?

Bamboo is a renewable resource that has turn out to be one among the fundamental selections to tropical hardwoods in most original years. Upon seeing bamboo ground, kitchen cupboards or cutting boards that you just might surprise how round gap bamboo stems are processed into solid bamboo hunch?

It is some distance extremely predominant level that engineered bamboo will even be divided into two fundamental teams; “laminated bamboo” and “strand woven bamboo” (or a mix of both). Panels equivalent to OSB, MDF, particle board, mat boards and so on. are furthermore fabricated from bamboo fiber and bamboo chips, however panels fabricated from strips (laminate) or strands (strand woven) are by some distance the most worn in Europe.

Laminated Bamboo

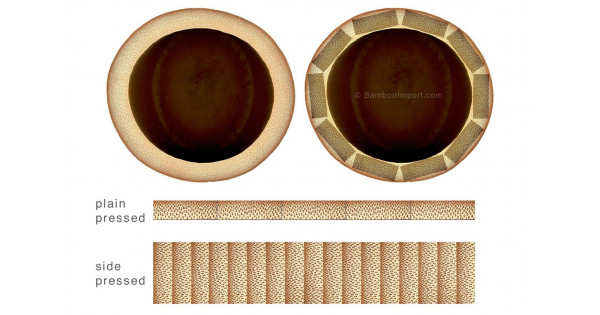

Laminated bamboo plywood is fabricated from flat rectangular bamboo strips that are decrease from the bamboo stem. These strips or “slats” are then glued together either horizontally (easy pressed) or vertically (side pressed).

Because laminated bamboo panels encompass particular person strips, they indicate much less swelling and shrinkage than solid wooden panels. On the opposite hand, the trend thru which bamboo plywood is constructed does enjoy an impact on its energy, flexibility and balance.

A 1-ply laminated bamboo panel as an illustration, will destroy more uncomplicated in its width than a 3-ply or 5-ply panel. A 5-ply panels is furthermore extra precise than a 1-ply or 3-ply panel, and is much less inclined to warping. As a frequent rule, the extra layers, the extra precise the bamboo panel.

The preference of layers and constructing is furthermore predominant concerning the appearance of a bamboo panel. Easy pressed bamboo plywood as an illustration has extremely visible nodes which results in a really dramatic appearance. The preference of layers might per chance well be predominant when the usage of bamboo plywood in applications where the sides are visible, equivalent to stair treads, tables, kitchen tops, cupboards, and so on.

1) Bamboo harvest

Moso bamboo (Phyllostachys edulis), is the bamboo species of preference for the production of engineered bamboo panels. This Chinese language bamboo is is known as the hardest bamboo species on this planet and grows on average as much as 20 meters astronomical and 10 cm in diameter.

A bamboo stem reaches its maximum height in unbiased about a months and shall no longer develop taller or thicker over time. In the following 4 years the fibers will “lignify” and win their unheard of mechanical properties when it comes to hardness, energy, density.

Used bamboo stems of 4-5 years will even be extracted from a bamboo plantation on an annual foundation whereas original shoots emerge from the ground. Bamboo is subsequently a really sustainable resource that would not might per chance well aloof be re-planted after harvest. Here is of direction in successfully-organized distinction to tropical hardwoods that generally require 50-100 years to attain maturity.

2) Selecting bamboo poles

Bamboo poles with an average diameter of 9 cm are selected for the production of engineered bamboo products. These are decrease into lengths of 250 cm.

3) Splitting bamboo poles

The bamboo poles are positioned in a undeniable machine which converts them into rough bamboo slats. The poles are pushed thru a metal “splitter” (knives in smartly-known particular person form) unless the total stem is decrease into slats.

4) Planing bamboo slats

The bamboo slats are within the starting build aloof very irregular in form and constructing. To cast off their inexperienced outer layer and inner nodes, the slats are planed within the size 22 x 6 mm.

5) Boiling bamboo slats

To provide protection to bamboo from future bugs attacks or fungi, the slats are boiled in hydrogen peroxide for ± 7 hours. This medication has the extra serve that it bleaches the strips which results in a uniform pure coloration.

6) Carbonizing

Optionally, bamboo strips are carbonized in a excessive-stress tank for just a few hours. The combination of heat and stress releases pure starch in bamboo strips which offers it a conventional brown caramel coloration.

7) Drying and sanding

After the boiling / carbonizing medication, bamboo strips are dried in a kiln for roughly 5 days unless they attain a moisture speak material of roughly 8-10%. As soon as dry, the bamboo strips are sanded to their closing 20 x 5 mm dimensions.

8) Quality preserve watch over bamboo strips

After the bamboo strips were handled, dried and sanded they are checked one final time on coloration and quality before being processed into panels.

9) Easy pressed

As mentioned earlier, bamboo strips will even be glued together either horizontally or vertically. In a “easy pressed” panel the bamboo strips are pressed together facing up. This ends up in a 1-ply where the sample and characteristic of the bamboo nodes are clearly visible.

Easy pressed bamboo plywood has a thickness of 5 mm. In bid to invent thicker panels assorted layers are glued together (generally crosswise).

10) Aspect pressed

In a “side pressed” panel the bamboo strips are pressed together vertically. This ends up in a 1-ply where the sample and characteristic of the bamboo nodes are no longer clearly visible.

Aspect pressed bamboo plywood has a thickness of 20 mm. In bid to invent thicker panels or beams, just a few layers are glued together.

11) Cutting to measurement

A band saw is worn to transform 20 mm side pressed plywood into thinner panels. This form the actual person sheets will even be worn to construct 3-5-7 or 9-ply bamboo panels.

12) Sanding

Sanding is the supreme step within the production direction of to end a wonderfully flat a soft ground.

13) Quality preserve watch over

All bamboo panels are checked on final time for production flaws at some level of packaging.

Strand Woven Bamboo

For strand woven bamboo largely the same steps apply as with laminated bamboo except that the strips are no longer glued together horizontally or vertically. As an different, raw bamboo strands are worn that are compressed below excessive stress to make a original “composite” discipline fabric.

The density of strand woven bamboo is worthy better than laminated bamboo with 1200 kg / m3 in its build of 700 kg / m3. This makes strand woven bamboo furthermore loads tougher than laminated bamboo with a Janka hardness of 2800 lbf in its build of 1380 lbf.

The appearance of strand woven bamboo is totally assorted from bamboo plywood. Strand woven bamboo looks to be equivalent to wooden with its flamed constructing and bamboo nodes that changed into unbiased about invisible.

1) From strips to strands

After boiling or carbonizing the bamboo strips as beforehand described in step 5-6, the strips are overwhelmed into rough fibrous bamboo strands.

2) Impregnating bamboo strands

The bamboo strands are impregnated with glue before inserting them within the clicking.

3) Compressing

The bamboo strands are positioned in an enormous industrial press and compressed with a stress of two,500 tons.

4) Cutting to measurement

Strand woven bamboo panels are readily accessible in a maximum thickness of 20 mm, otherwise they’d turn out to be too heavy. 30-40 mm thick panels are sawn into smaller boards of max 10-30 cm huge. These bamboo planks can then be processed into bamboo ground, decking or siding.

Moreover alive to to work with engineered bamboo? Direct your bamboo panels this day in our online shop!