Researchers abet manufacture sustainable polymers

Researchers on the FAMU-FSU Faculty of Engineering have made original discoveries on the outcomes of temperature on sustainable polymers. Their findings could maybe additionally abet the swap to perform plastics which shall be better for the atmosphere.

“Plastics fabricated from petroleum, a non-renewable resource, stay too long in our land and water when discarded,” acknowledged Rufina Alamo, a professor within the Division of Chemical and Biomedical Engineering. “We are researching how sustainable polymers are heated and cooled so we could maybe additionally perform more ‘environmentally pleasant’ plastics.”

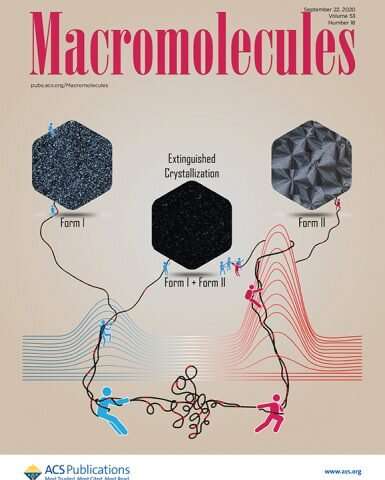

Alamo and dilapidated doctoral candidate Xiaoshi Zhang, now a postdoctoral analysis fellow at Penn Insist, recently published the work in a series of papers that listen on the crystallization of “green” polymers. The most contemporary paper appears as the masks article in Macromolecules, a number one journal for polymer science.

“There might perhaps be a worldwide motivation to rework how basically the most arresting volume of plastics are made,” Alamo acknowledged. “Polymer chemists and physicists are working exhausting to perform change materials to total problematic plastic slay.”

Determining the proper temperature for processing is key to producing better materials that might perhaps abet scientists change inexpensive polymers fabricated from petroleum with economically viable, sustainable polymers.

“How the polymer is melted and cooled to perform the desired form is mandatory,” Alamo acknowledged. “We are attempting to attain the intricacies of crystallization to extra realize the transformation path of.”

The workers is finding out a form of polymer known as “long-spaced polyacetals,” which shall be worn in plastics. Synthesized in a laboratory on the College of Konstanz in Germany, the long-spaced polyacetals Alamo’s workers worn attain from sustainable biomass. They dangle a polyethylene backbone linked with acetal groups at staunch equal distances. The vogue combines the toughness of polyethylene with the hydrolytic degradability of the acetal workers. This plan of polymer is difficult but breaks aside more with out dispute with water than frail polymers.

“What we stumbled on is all these polymers crystalize in an irregular manner when cooled after melting,” Alamo acknowledged.

For the duration of the cooling path of, molecules that glance love curly strands of spaghetti of melted plastics disentangle to bear crystals and are to blame for the toughness of the last enviornment cloth. Alamo’s workers showed that polymer crystallization is controlled by molecular occasions that defend space on the crystal progress front.

The researchers stumbled on that as soon as cooled impulsively, these polyacetals modified into not easy and crystalline, and the molecules self-assemble in a form of crystal termed “Grasp I.” When cooled slowly, the enviornment cloth is additionally very crystalline, but the crystals formed are pretty varied and are dubbed “Grasp II.” When cooled at intermediate temperatures, the enviornment cloth does not solidify in any respect. This phenomenon has never been seen in every other crystalline polymers, in accordance with the researchers.

“For crystals to be formed, an vitality barrier first have to be surmounted,” Alamo acknowledged. “At low temperatures, crystals are with out dispute formed. At excessive temperatures, crystals are more stable, and at intermediate temperatures, the crystals compete to bear, and the enviornment cloth can not solidify.”

“It is a long way a important discovery because it is an crucial key to working out how the plastics we exercise modified into solids,” she acknowledged. “We desire to present the swap with basically the most arresting transformation processes doable. We desire sustainable plastics that place not warp or have dispute solidifying.”

The analysis could maybe additionally present original strategies of manufacturing plastics that might perhaps be more economical to perform and sustainable.

Extra recordsdata:

Xiaoshi Zhang et al, Crystallization of Long-Spaced Precision Polyacetals II: Produce of Polymorphism on Isothermal Crystallization Kinetics, Macromolecules (2020). DOI: 10.1021/acs.macromol.0c01443

Quotation:

Researchers abet manufacture sustainable polymers (2020, September 25)

retrieved 26 September 2020

from https://phys.org/news/2020-09-sustainable-polymers.html

This document is enviornment to copyright. Other than any enticing dealing for the cause of private survey or analysis, no

fragment could maybe additionally be reproduced with out the written permission. The relate material is equipped for recordsdata purposes easiest.